Basic Suppliers Inside the HWB Cover B2B Supply Chain

For businesses looking to source, manufacture, or private label Hot water bottle covers, understanding this ecosystem is key to ensuring quality, efficiency, and cost-effectiveness. Let's unravel the B2B network that transforms raw materials into the finished product on a retailer's shelf.

The Core Players: A Symphony of Specialization

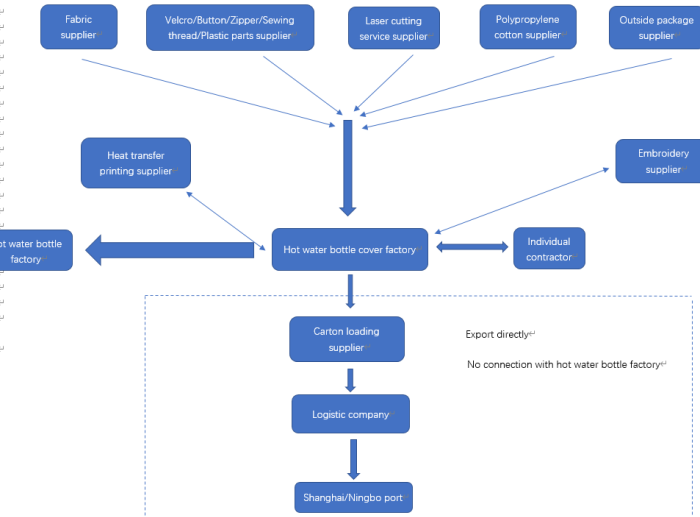

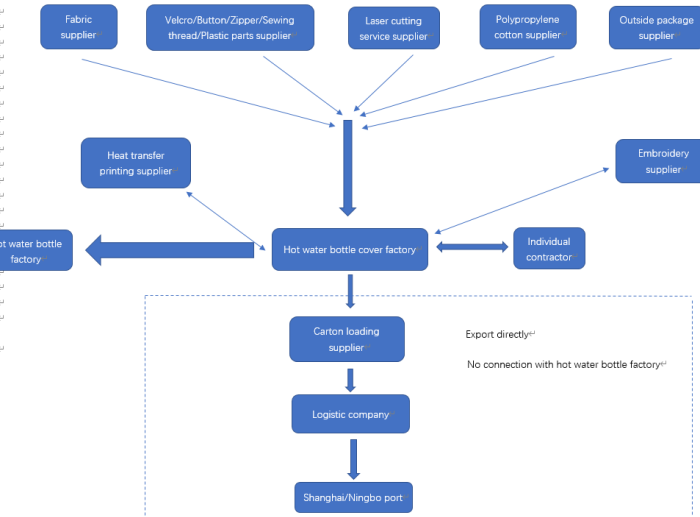

The diagram illustrates a clear division of labor, which is the hallmark of an efficient B2B industrial cluster. Each supplier focuses on a core competency, providing specific components or services to the next link in the chain.

1. The Material Foundation: From Fibers to Fasteners

Before a single stitch is made, raw materials must be sourced from dedicated suppliers. This stage is all about raw material specifications and bulk purchasing.

Fabric Supplier: The foundation of any cover is the fabric. B2B buyers work directly with fabric suppliers to select textures, colors, and materials—from soft fleece to durable cotton—based on performance and aesthetic requirements.

Polypropylene Cotton Supplier: This is the unsung hero of the plush, padded feel. As a B2B supplier, they provide the soft, insulating filling in large volumes, ensuring consistency in thickness and quality.

Velcro/Button/Zipper/Sewing Thread/Plastic Parts Supplier: The devil is in the details. These specialized suppliers provide the functional components. A B2B buyer needs reliable partners for these seemingly small but critical parts, as a faulty zipper or weak thread can ruin the entire product.

2. The Manufacturing & Customization Hub: Adding Value

This is where raw materials are transformed and given their final look and feel. These suppliers are the creative engine of the supply chain.

Laser Cutting Service Supplier: Precision is paramount. Laser cutting suppliers offer clean, sealed edges that prevent fabric from fraying, ensuring a high-quality, durable component ready for assembly(Some cover factory running their own cutting machines).

Embroidery Supplier & Heat Transfer Printing Supplier: These are the go-to partners for branding and decoration. Whether it's a woven logo, a floral design, or a custom pattern, these B2B suppliers add the visual value that makes a product marketable. Brands can choose the texture of embroidery or the vibrancy of heat transfer prints.

Outside Package Supplier: The product isn't complete without its packaging. This B2B partner designs and manufactures the tags, boxes, or polybags that protect the product and present it attractively to the end consumer.

3. The Assembly & Logistics Experts: Bringing It All Together

With all the custom pieces ready, they must be assembled and shipped.

Hot water bottle cover Factory: This is the central assembler. They receive components from the fabric, accessory, and customization suppliers to sew the final cover. In this B2B relationship, they are the primary manufacturer, turning a bill of materials into a finished inventory unit.

Carton Loading Supplier: Efficient and secure transport is vital. This supplier specializes in packing finished covers into cartons, optimizing space to reduce shipping costs and ensuring the products are protected for their journey.

Logistics Company: The bridge to the global market. They manage the complex paperwork, consolidation, and shipping from ports like Shanghai or Ningbo to international buyers.

The Strategic B2B Advantage: Why This Matters

This structure offers significant benefits for businesses looking to enter or optimize the hot water bottle cover market:

Scalability & Flexibility: You are not tied to a single, monolithic factory. If you need a rush order on custom printing, you can scale up with the heat transfer printing supplier. If you want to test a new fabric, you source it directly from the fabric supplier. This modularity reduces risk and increases agility.

Access to Specialized Expertise: You benefit from the accumulated expertise of each niche player. The embroidery supplier has mastered their machines; the laser cutter understands the material's behavior. This leads to a higher quality final product than if one generalist attempted to do everything.

Cost Efficiency: By leveraging suppliers who focus on a single process, you benefit from their economies of scale. They buy thread, fabric, or ink in massive quantities, passing those savings on to you. The "individual contractor" in the diagram represents this hyper-flexible, often cost-effective labor for specific tasks.

Control Over Quality: You can audit and qualify each supplier individually. This creates a transparent chain where you can pinpoint the source of a quality issue—be it a faulty zipper or a misaligned print—and address it directly with the responsible B2B partner.

A Note on Strategic Independence

An interesting aspect of the diagram is the note: "No connection with hot water bottle factory."

This highlights a strategic choice. The cover supply chain is entirely independent from the rubber bottle manufacturers. This allows businesses to:

Mix and Match: Source high-quality covers from one specialized network and pair them with the best rubber bottles from another.

Focus on Core Competency: Companies can specialize purely in the soft goods (the covers) without the complexities and safety regulations of manufacturing the rubber components.

Branding Opportunities: It allows for a diverse range of cover styles and designs that can be paired with standardized, universally-sized bottles, maximizing market appeal.

Conclusion

The journey from a bolt of fabric to a beautifully packaged hot water bottle cover is a testament to the power of B2B collaboration. By understanding and leveraging this network of specialized suppliers—from the polypropylene cotton filler to the port-side logistics company—businesses can build a resilient, high-quality, and scalable product line.